Menuiserie

VUE ENTREPRISE

14 résultats

14 résultats

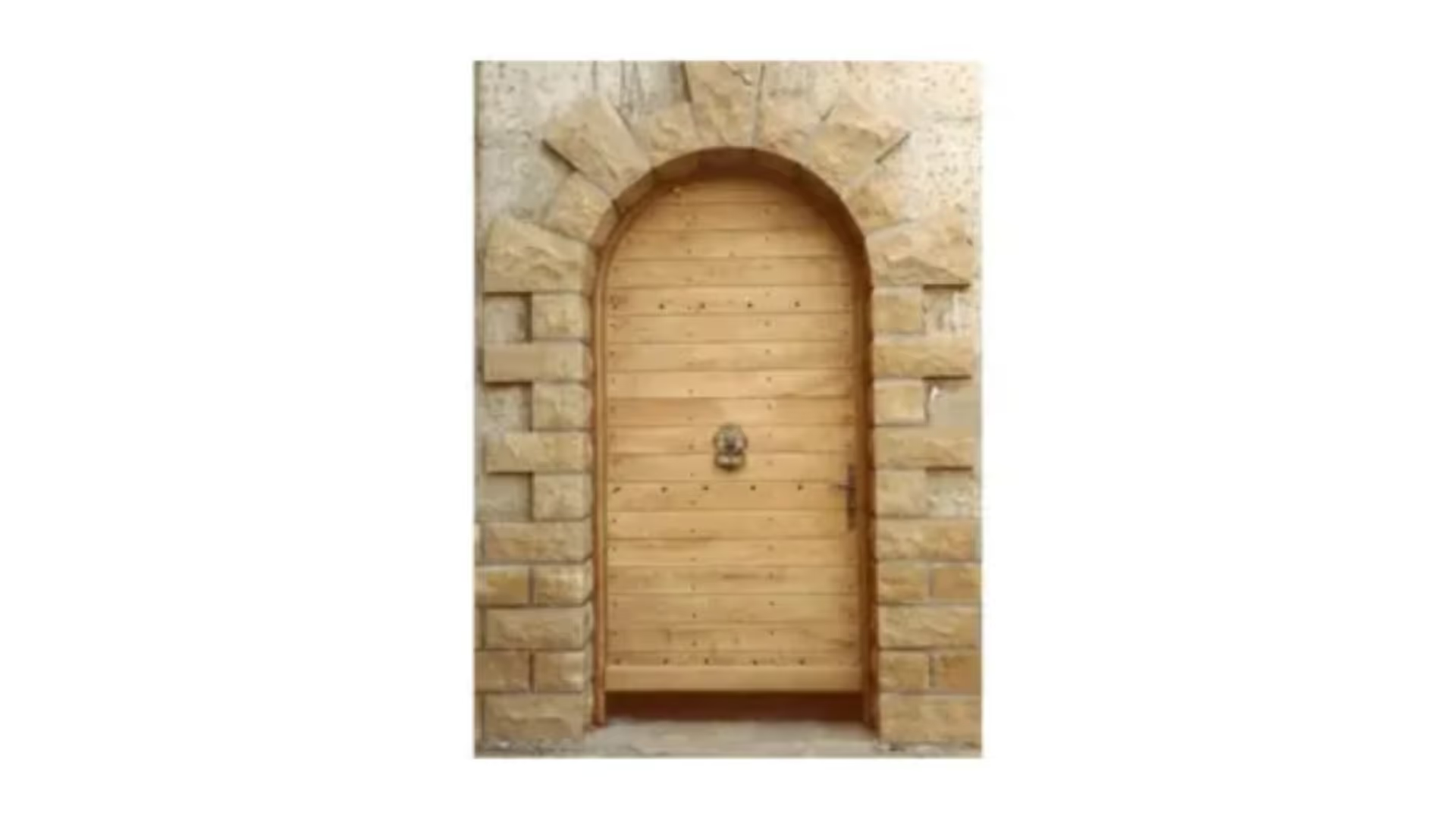

Porte plein cintre

Menuiserie

Mixte bois/alu

Menuiserie

Portes d'entrée

Menuiserie

Porte avec vitraux

Menuiserie

Menuiseries à recouvrement

Menuiserie

Fenêtre cintre surbaissé

Menuiserie

Coulissants

Menuiserie

Fenêtre avec petits bois

Menuiserie

Menuiseries à l'ancienne

Menuiserie

Volets bois

Menuiserie

Porte fenêtre bois 2 vantaux

Menuiserie

Fenêtre patrimoine

Menuiserie

fenêtre avec volet intégré

Menuiserie

Porte-fenêtre avec volets

Menuiserie

Comment choisir sa menuiserie extérieure ?

Dans le cadre du travail du bois, la menuiserie consiste à assembler du bois, du bois d'ingénierie ou des substituts synthétiques (comme le stratifié) pour produire des articles plus complexes. Il existe des assemblages pour le travail du bois qui utilisent des fixations mécaniques, des attaches ou des adhésifs, et d'autres qui n'utilisent que des éléments en bois (comme les chevilles ou les assemblages à tenon et mortaise).

La force, la flexibilité, la résistance, l'apparence et d'autres caractéristiques des assemblages en bois dépendent des matériaux utilisés et de l'objectif de l'assemblage. Par conséquent, différentes techniques d'assemblage sont utilisées pour répondre à différentes exigences. Bien que certains concepts se recoupent, la menuiserie utilisée pour construire une maison peut différer de celle utilisée pour fabriquer des armoires ou des meubles.

Types de menuiserie en bois

Le concept d'assemblage du bois est l'un des plus fondamentaux du travail du bois. Sans la possibilité d'assembler deux pièces de bois de manière solide, toutes les pièces de menuiserie seraient des sculptures taillées dans une seule pièce de bois. En raison des nombreux types d'assemblage du bois, un menuisier peut choisir parmi un certain nombre de joints différents, en fonction du projet. Vous serez sur la bonne voie pour devenir un menuisier très accompli si vous maîtrisez ces concepts de menuiserie.

Assemblage bout à bout de base

L'assemblage bout à bout est l'un des types les plus élémentaires d'assemblage du bois. Lorsqu'une pièce de bois est aboutée à une autre (généralement à angle droit ou à l'équerre par rapport à l'autre planche), elle est fixée à l'aide d'attaches mécaniques. Les chantiers de construction utilisent souvent ce type de joint pour l'ossature des murs. Découvrez quand utiliser un joint bout à bout et quand choisir un autre type d'assemblage de bois.

Assemblage bout à bout en onglet

Les assemblages bout à bout en onglet sont similaires aux assemblages bout à bout de base, sauf qu'ils sont assemblés en angle plutôt qu'à l'équerre. Un joint à onglet ne laisse pas apparaître le grain terminal et est donc plus esthétique. Cependant, les joints à onglet ne sont pas très solides.

Joint à mi-longueur

Dans un assemblage à mi-longueur, la moitié de chacune des deux planches est enlevée de manière à ce qu'elles se rejoignent à fleur. Il est évident que ce type d'assemblage de bois peut affaiblir la résistance de deux planches adjacentes, mais il s'agit également d'un assemblage plus solide que les joints bout à bout. Malgré ses inconvénients, ce type d'assemblage est tout à fait souhaitable dans certains projets.

Joint à rainure et languette

Des fixations peuvent être utilisées pour joindre deux planches d'équerre l'une à l'autre le long d'un bord long. Les assemblages à rainure et languette sont toutefois plus solides et offrent davantage de surfaces contiguës, ce qui est particulièrement utile si vous prévoyez de les coller.

Assemblage à tenon et mortaise

L'assemblage à tenon et mortaise est une méthode classique de travail du bois. Depuis les premiers jours du travail du bois, ces assemblages figurent parmi les méthodes les plus solides et les plus élégantes d'assemblage du bois. Apprenez ces méthodes pour créer de beaux assemblages à tenon et mortaise.

Assemblage en biscuit

Pour maintenir les planches en place le long des bords (comme un assemblage à rainure et languette), on peut découper des fentes dans les planches et utiliser des gaufrettes de bois de hêtre (appelées biscuits). Les menuisiers modernes utilisent ce type d'assemblage pour créer des plateaux de table, en se fiant à la colle et au gonflement du biscuit de hêtre pour fixer les planches. Pour obtenir des résultats fiables, apprenez à tailler des rainures régulières.

Joint de poche

L'assemblage à poche est un type de menuiserie qui consiste à découper une fente entre deux planches et à prépercer un avant-trou à un angle. Un gabarit commercial est généralement utilisé pour ce pré-perçage, car il doit être très précis. Les joints creux sont parfaits pour les cadres de façade d'armoires et d'autres applications qui ne nécessitent pas une grande résistance. Découvrez comment créer des joints creux dans vos projets de travail du bois.

Dado

Une rainure n'est rien d'autre qu'une rainure carrée sur une planche où une autre planche peut être insérée. Souvent utilisé pour assembler du contreplaqué, par exemple lors de la construction d'une armoire, ce type de joint est similaire à l'assemblage à rainure et languette. Découvrez quand utiliser une rainure et comment la couper correctement.

Feuillure

La feuillure est un autre assemblage de bois couramment utilisé dans l'ébénisterie. Il s'agit essentiellement d'une rainure pratiquée le long du bord d'une planche. Les armoires et autres assemblages similaires utilisent souvent des feuillures pour fixer l'arrière aux côtés, ce qui renforce considérablement l'assemblage. L'utilisation de feuillures est facile lorsque vous savez comment les couper proprement.

Joint à queue d'aronde traversant

Parmi toutes les méthodes d'assemblage du bois, la queue d'aronde traversante est peut-être la plus vénérée. Une queue d'aronde classique est belle, solide et ajoute une touche de classe à toute pièce. Les queues d'aronde traversantes peuvent être créées par découpe manuelle ou par usinage à l'aide d'un gabarit. Découvrez comment créer un assemblage à queue d'aronde de qualité.

Queue d'aronde en demi-aveugle

Lorsqu'un assemblage à queue d'aronde est la meilleure option, les deux bords de la queue d'aronde ne doivent pas être visibles. Vous ne voulez pas voir l'extrémité de la queue d'aronde traversante sur la façade d'un tiroir, par exemple. Les queues d'aronde semi-aveugles sont le meilleur choix pour ce type d'assemblage. L'utilisation de ce type de menuiserie vous aidera à réaliser un assemblage à queue d'aronde en demi-aveugle propre, solide et beau.